Temperature Forcing Applications

ATE Testing Automation

Enhance even more your ATE integration with temperature forcing systems from Mechanical Devices by installing testing automation fixtures. In-house engineering capabilities allow us to design, develop and implement best solutions for your hassle free and efficient testing.

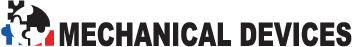

Optical transceivers Thermal Testing

With state of the art design, Mechanical Devices units stimulate optical transceivers to the desired temperature precisely and consistently by direct contact with a thermal module adapter. Thermal head tip is designed for direct contact with the module through a window in module’s cage. Thermal controller with 19”-rack body case and pneumatic engage and release mechanism makes this solution a perfect fit for production testing.

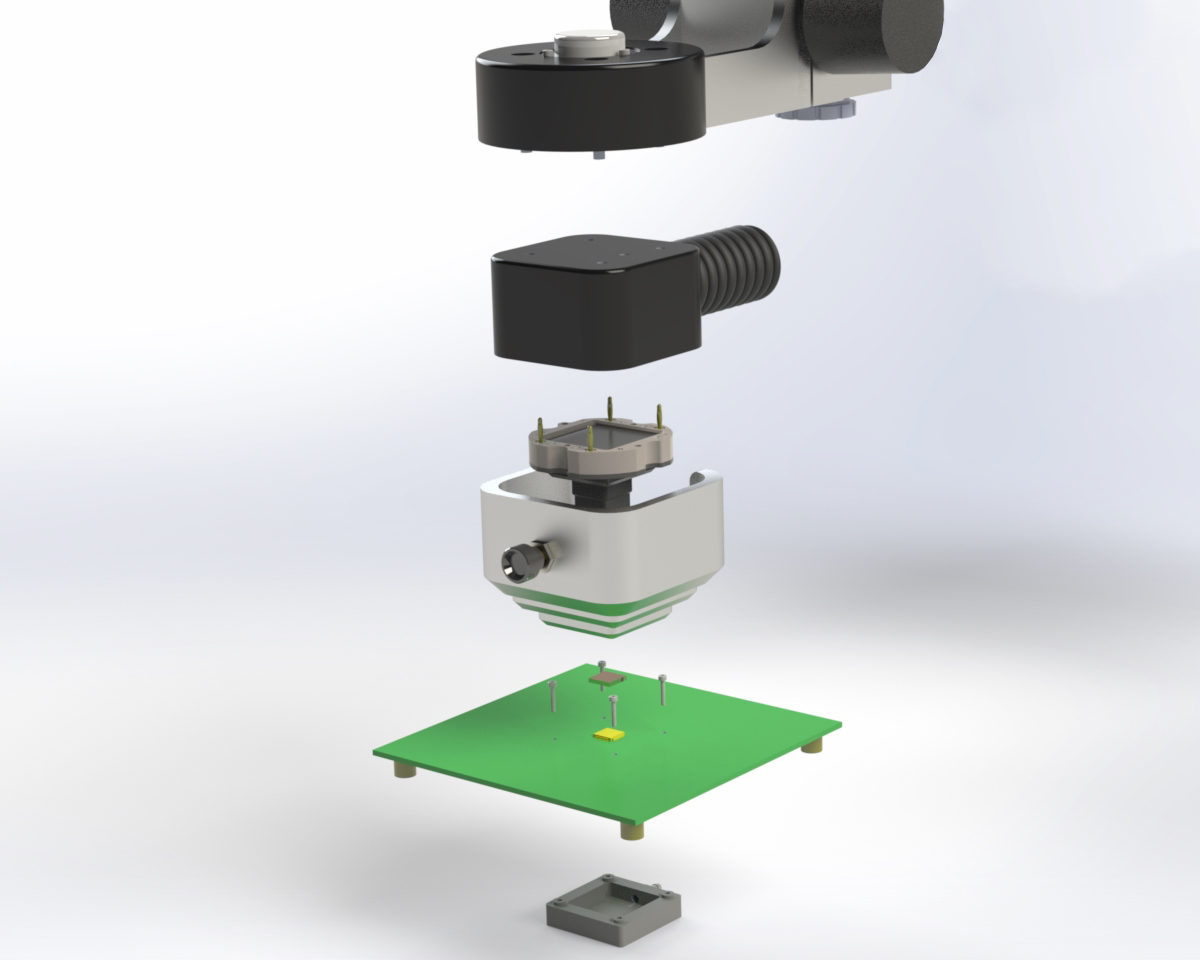

Transistor devices (MOSFETs) Thermal Testing

Mechanical Devices – Advanced Thermal Solutions – is a leading designer, developer and global supplier of state of the art thermal solutions to provide fast, precise and reliable method for on-chip thermal testing of various transistor devices (MOSFETs, BJTs, IGBTs) in wide range of temperatures. Specially designed quick attach and release feature allows to consistently test multiple devices even having various form factors. Switching from one device to another will take single moments leaving all the spared time to data collection.

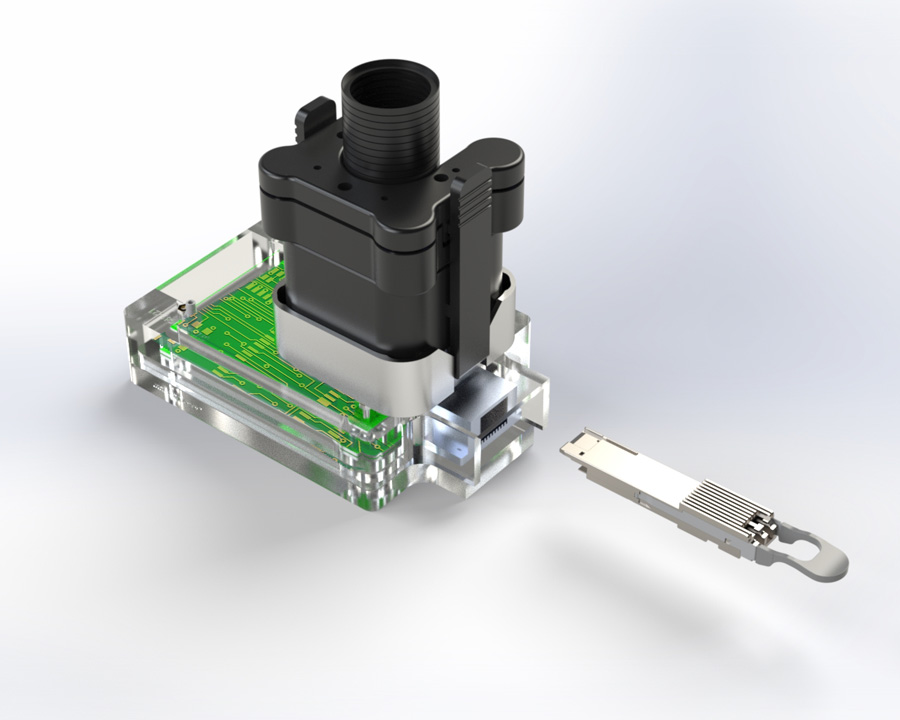

Thermal RF Testing

In collaboration with DVTEST, Mechanical Devices is proud to announce a breakthrough in RF shielded thermal testing of integrated circuits. State of the art direct contact temperature forcing systems can now be paired with the industry leading RF enclosure, to allow manufacturers to easily perform IC testing over temperature in a controlled RF environment. “RF Testing at extreme temperatures continues to be a challenge not only for the semiconductor industry but the entire electronics industry as a whole – thanks to this new partnership, we can now provide a robust and viable solution” says Serge Stephan, Bus Dev. Manager of DVTEST.

ATE Integration

As the race to bring new semiconductor products to market intensifies, the industry looks for innovative ways to enhance profitability, increase reliability and reduce the time to market.

Take advantage of ramp times and easy bring up. Liquid free design of temperature forcing systems will allow a risk free testing while using costly equipment and load boards. Protect your testing time with hassle free and maintenance instrument. Enjoy fully programmable interface of MD to integrate thermal control into your tester’s environment. Direct differential voltage option to control your Tj easily and reliably.

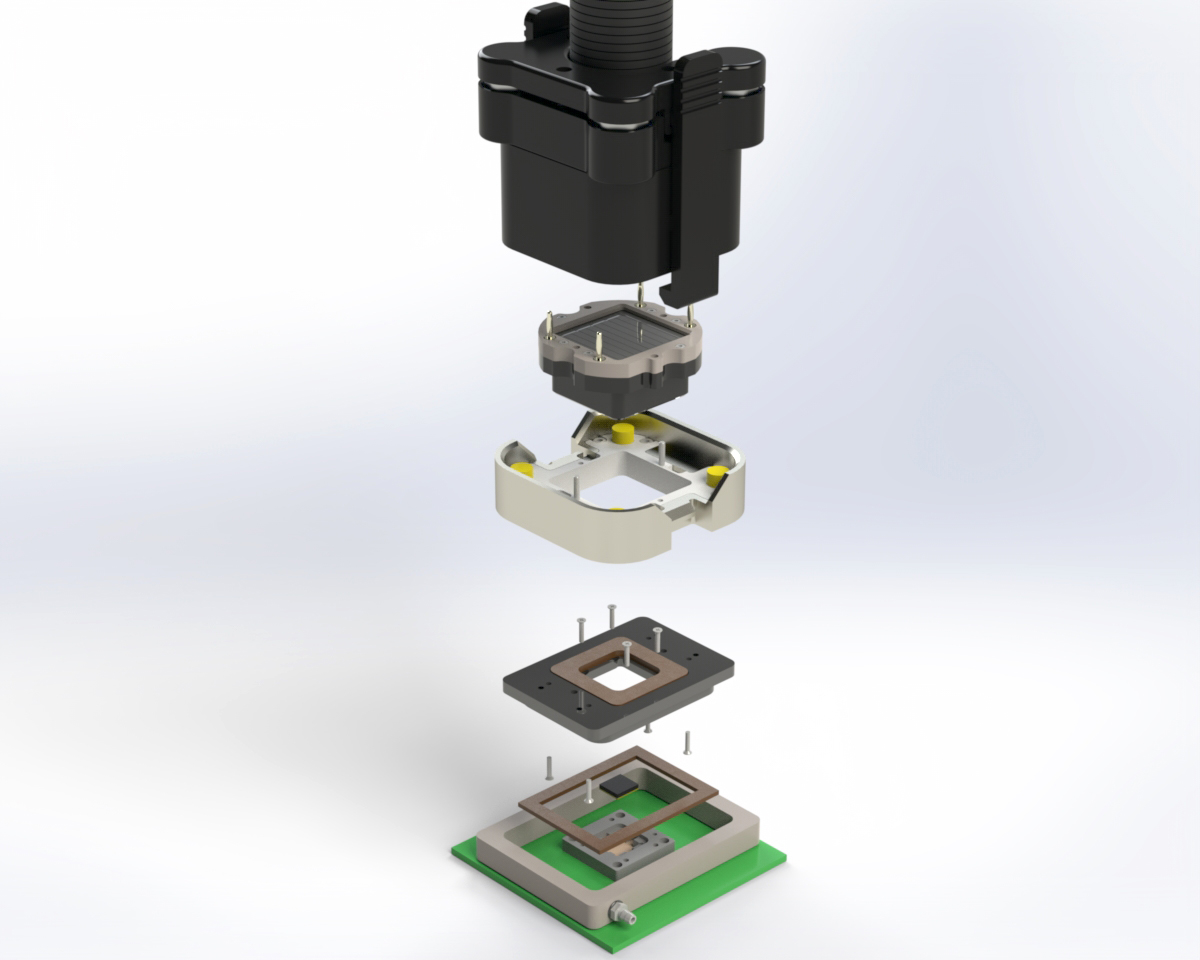

Socketed Applications

With over 15 years of experience in integrating various socketed applications, Mechanical Devices easily and reliably provides solutions for testing your DUTs under temperature. Quick connect and automatic force application provides quick DUT exchange, consistent testing conditions and operator-error free operation.

In-house engineering capabilities and expertise will provide you with the best thermal performance solution across various socket and PCB designs.

Frost free accessories and automatic control function on-board of every temperature control system from Mechanical Devices provide risk free 24/7 testing

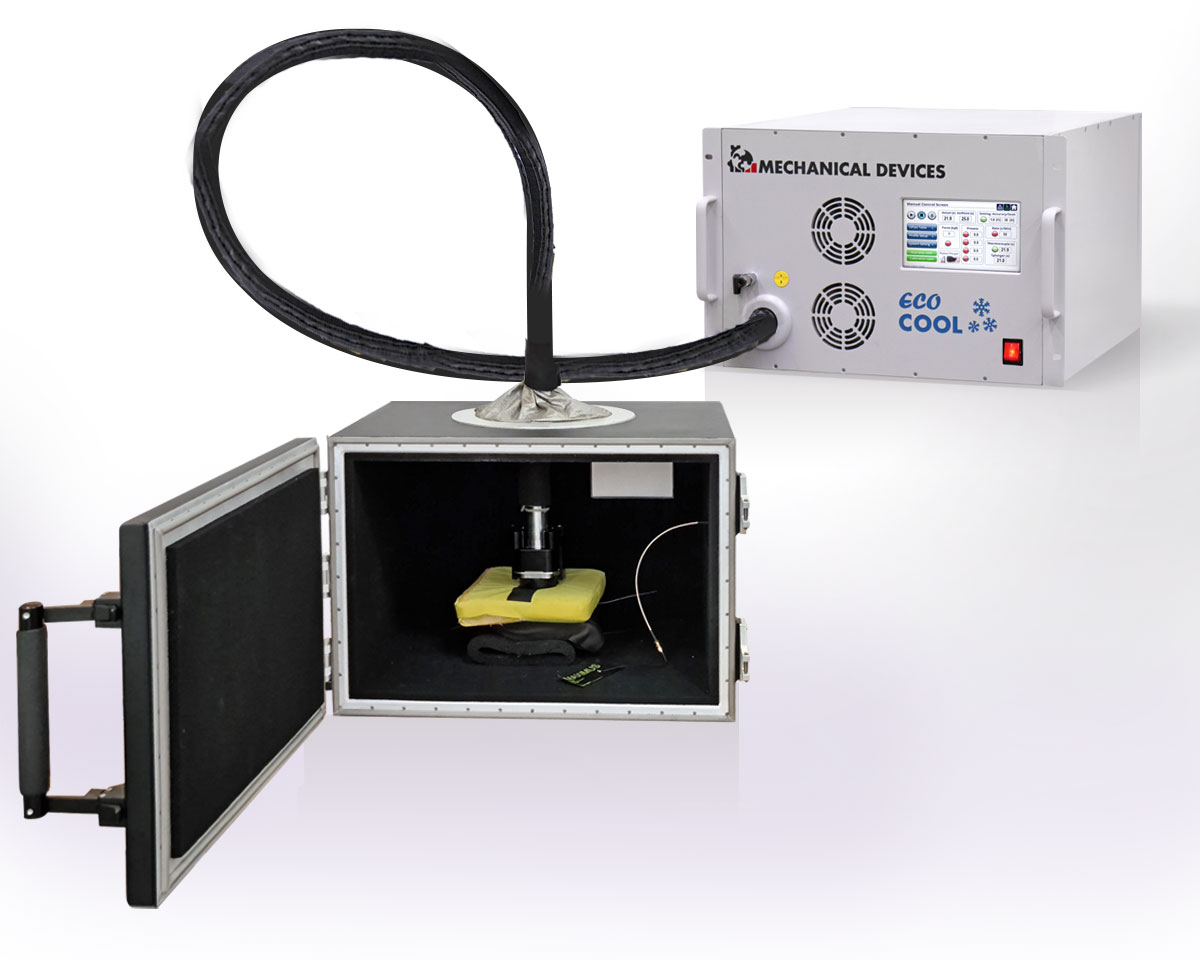

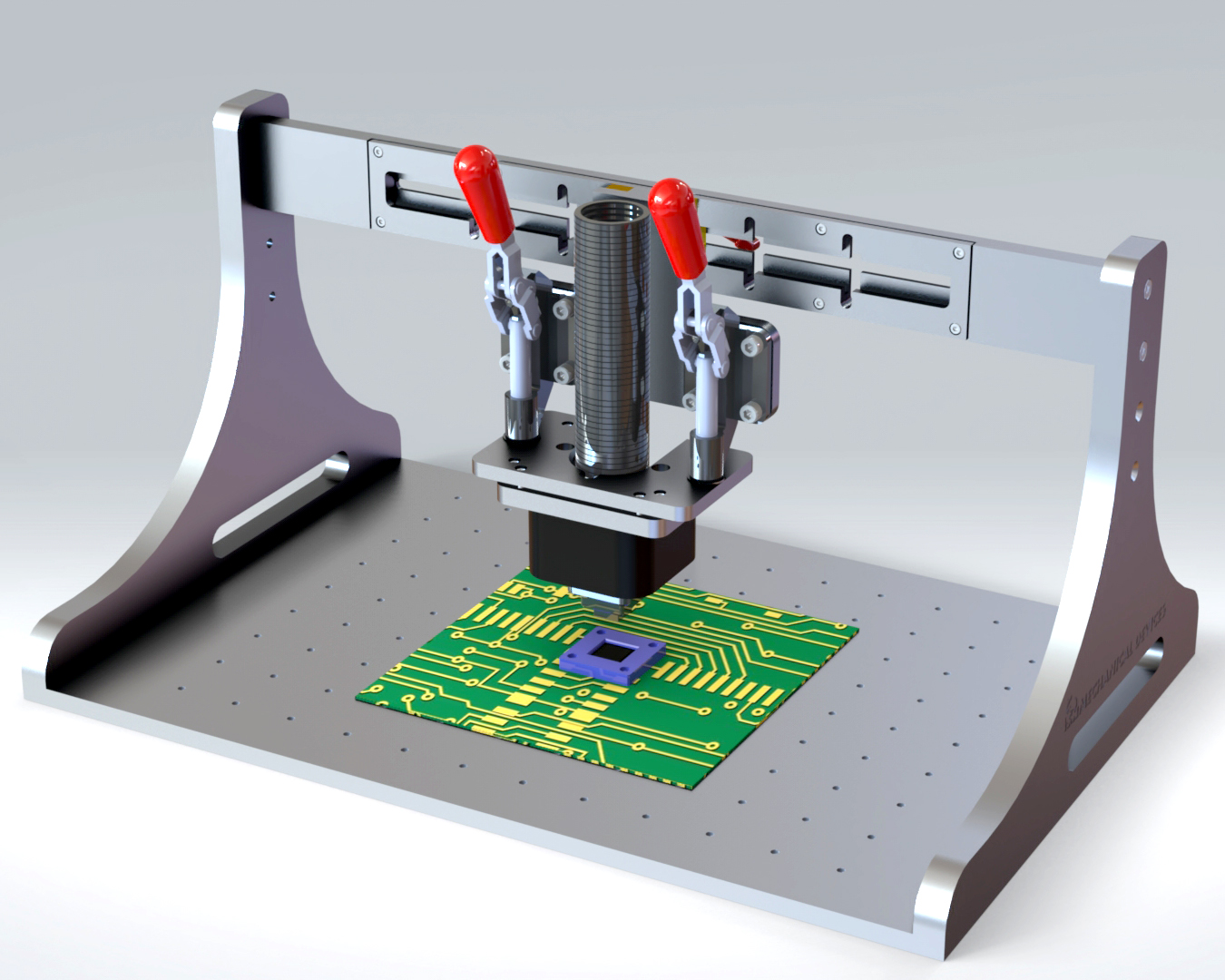

Soldered down Applications

Testing of soldered down devices had never been easier and more efficient. Generic package adapters (plungers and tips) matched with various boom-stand toggle clamp and gantry fixture will provide fast and precise temperature cycling environment for your application.

Frost free accessories and automatic control function on-board of every temperature control system from Mechanical Devices provide risk free 24/7 testing.

Some Applications of need Temperature Forcing systems:

- Back-End Test

- Cooling the IC while Stress Full Cycle

- IC Handler Verification

- Incoming Inspection

- Functional Test

- Failure Analysis

- Final Test

- Product Engineering

Benefits of Fluid-Free Operation

FlexTC/ MaxTC are Fluid Free – the systems do not contain any fluids and it do not require external chillers for their operation.

FlexTC/ MaxTC are self-contained standalone systems that completely eliminate the need for chillers. Chiller-based systems always run the risk of fluid leaks that can cause severe damage to the tester. FlexTC/ MaxTC in that they are fluid free means that their thermal head operates safely on tester heads without risks of spills or leaks.