MaxTC Power Plus G4

MaxTC Power Plus G4

Extreme Power Temperature Forcing System

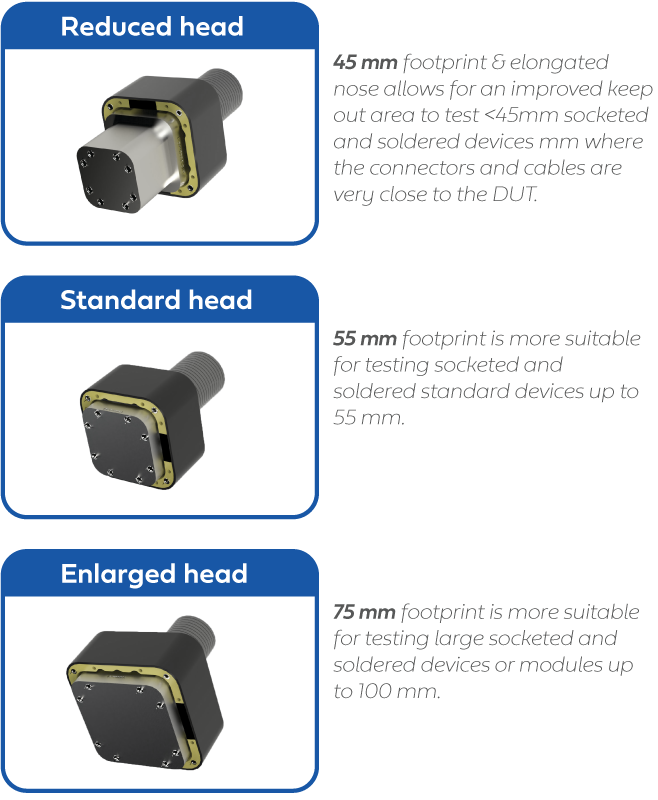

NEW G4 – MaxTC Power Plus was designed with high power and flexibility in mind, allowing for customization to suit different package and interface variations. The system allows for forcing temperature across a wide range of high power device sizes and types, whether socketed or soldered to board. With state of the art design and technology the Max TC Power Plus unit stimulates DUT to the desired temperature precisely and consistency by direct contact with a powerful thermal head.

High Power: 400W@-55°C

High Power: 400W@-55°C

Temp. Range: -75°C to 200°C

Temp. Range: -75°C to 200°C

Quiet operation: 55dBA

Quiet operation: 55dBA

Maintenance FREE

Maintenance FREE

Frost FREE operation

Frost FREE operation

This Product includes and protected by patents.

Proprietary of Mechanical-Devices Ltd 2024©

CE Certified and ISO 9001:2015 Certified.