INTEGRATED PRECISION SOLUTIONS

FOR TESTING IC DEVICES

OVER TEMPERATURE

For over 10 years, our inventions have led IC manufacturers to adopt our innovative thermal solutions.

MD (Mechanical Devices) – Advanced Thermal Solutions is a leading designer, developer and global supplier of state of the art thermal solutions and a broad range of thermal forcing systems for testing IC devices over temperature.

Mechanical devices temperature control units provide fast, accurate, stable and cost effective solutions, using advanced technology to serve the needs of test engineers.

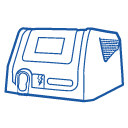

With the industry’s state-of-the-art temperature control units, Flex TC, Max TC, ECO Cool and Power Plus, Mechanical devices is changing the way in which testing and temperature control is performed.

These changes create improved efficiency and accuracy of the IC testing process enabling semiconductor manufacturers to enhance their profitability and test reliability. MD’s end-user customers are among the world’s top semiconductor manufacturers. The Thermal Control units can be well integrated with Bench, ATE and SLT testing setups.

Mechanical Devices is headquartered in Haifa Bay, Israel with a branch office in Santa Clara, CA. and a number of sale representatives at key locations throughout the United States, Canada, Asia and Europe.

Test your IC Device with confidence without ever

worrying about Temperature requirements.

Temperature range options from -75°C to 200°C.

Cooling power options can reach -50°C @ 400W.

Thermal stream, chamber and chiller replacement.

To get the best thermal solution for your testing requirements

The ORIGINAL Direct Contact TCU, free of fluid and compressed air for High Reliability Testing.

MD Thermal control units were designed with high performance and flexibility in mind, allowing for customization to suit different package and interface variations. The system allows for temperature forcing on any package. With state of the art design and technology, MD units stimulates the DUT to the desired temperature precisely and consistently via direct contact with a thermal head’s plunger.

MD Thermal control units are self-contained, for real plug and play setup.

The thermal head uses direct contact whereby an interchangeable plunger creates direct contact with the DUT and drives Tc or Tj to the required temperature. A temperature sensor embedded in the plunger surface provides real-time temperature data. The system controller contains a touch-screen for temperature control options, as well as a LAN port for full automation. For cold testing, a condensation free environment is maintained