Test your IC Device over temperature

with confidence

with the most innovative

Thermal Control Units

Temperature forcing systems.

Will your IC and sensor

perform in the most extreme

temperature environments?

220°C -75°C

-75°C

Innovative Temperature Forcing Systems for Characterization and validation of IC devices

Direct Contact TCU – free of fluid and compressed air.

When developing IC devices, reliable results are extremely important. MD thermal control units simplify and improve your testing today and in the future. It offers best thermal control capabilities. Let our Thermal Control Units work for you while you plan your next test.

Mechanical Devices provides a variety of Temperature Control Units designed with high performance and flexibility in mind, allowing for customization to suit different package and interface variations. The systems have a wide temperature ranges ideal for testing different IC devices under most extreme temperature conditions. The units are easy to use with full remote control capability for automation.

Mechanical Devices temperature control units provide fast, accurate, stable and cost effective solutions, using advanced technology to serve the needs of IC test engineers.

All of the Mechanical Device’s units are self-contained, Maintenance FREE, Plug-and-Play operation on Bench, ATE & SLT

Innovative Temperature Forcing Systems for evaluation and validation of IC devices.

Direct Contact TCU – free of fluid and compressed air.

Temperature forcing systems are a Fast, Accurate and Affordable solution for testing your DUT in the desired temperatures by direct contact.

Unique frost and liquid free technology guarantees precise performance evaluation.

Mechanical Devices provides a variety of Temperature Control Units designed with high performance and flexibility in mind, allowing for customization to suit different package and interface variations.

Our systems have a wide temperature ranges ideal for stress testing different IC devices under most extreme temperature conditions in low maintenance, easy to use form with full remote control support.

All of the Mechanical Device’s systems are self-contained and integrate Plug-and-Play setup.

The future of semiconductor industry is exciting.

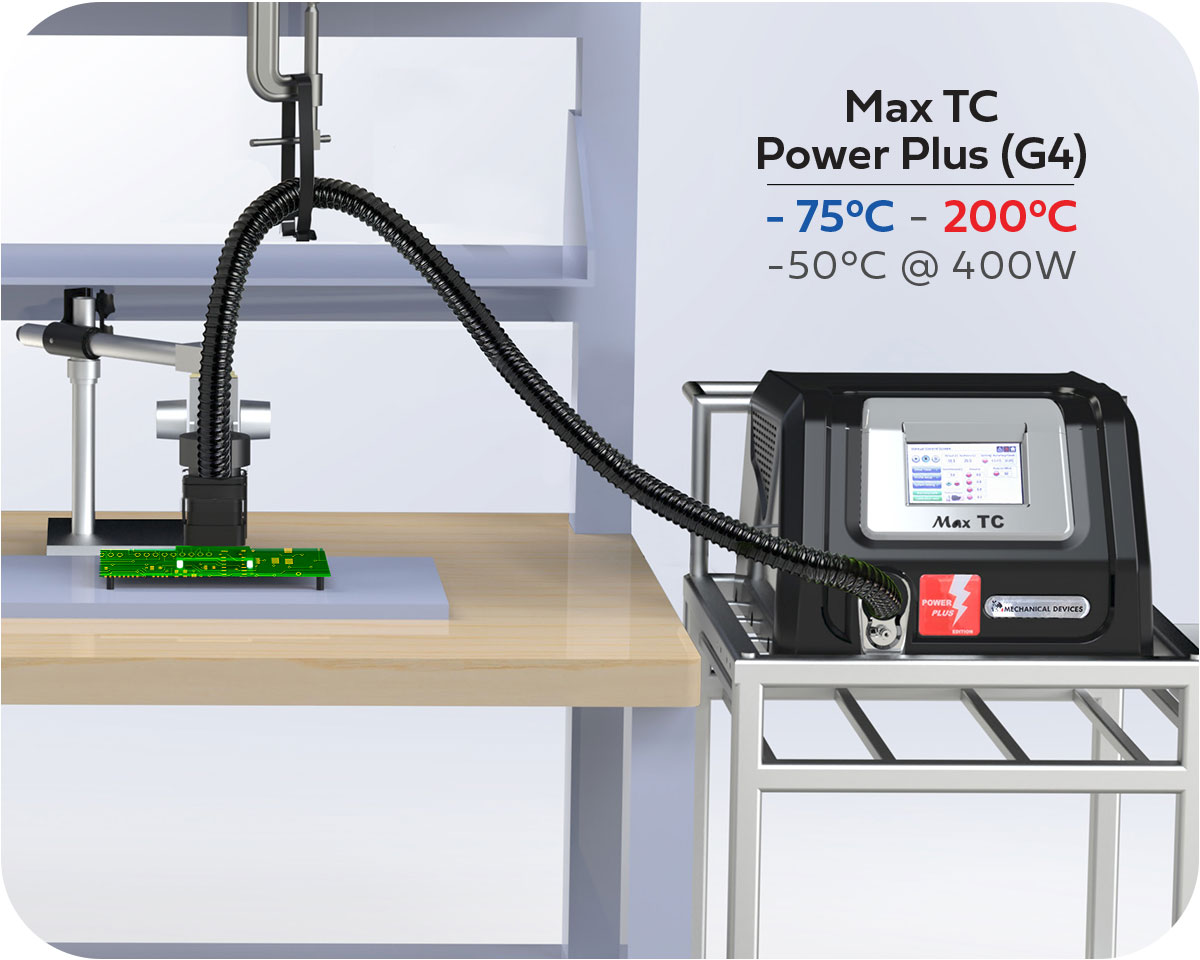

Max TC Power Plus G4 is undoubtedly the best way for testing IC devices over Temperature

Mechanical Devices Ltd Develops, Produces and Supplies state-of-the-art thermal solutions to the worldwide semiconductor industry.

-60 to 220°C

Up to 25°C/min

-30 to 200°C

0°C @ 200W

-60 to 220°C

Up to 25°C/min

-30 to 200°C

0°C @ 200W

-50 to 155°C

-32°C @ 20W

-75 to 200°C

-50°C @ 400W

-70 to 175°C/200°C

-40°C @ 90W

-30 to 200°C

0°C @ 200W

-50 to 155°C

-32°C @ 20W

-75 to 200°C

-50°C @ 400W

-70 to 175°C/200°C

-40°C @ 90W

-30 to 200°C

0°C @ 200W

And we will work out your individual

temperature solution

Spirit of innovation

MD, an industry leader in phase change technology for IC testing covering a wide spectrum of IC products. With missions of Phase change technology and wide range of thermal solution sold worldwide more than 13 years, MD has established its reputation over the years and continues to reinforce it with world class support and creative ways to keep the systems operating reliably and efficiently.

It is also the first company to invent a uniquely designed change phase direct contact TCU. Coupled with an integrated controller and its proprietary direct contact change phase, has raised the standard in direct contact thermal solution.

Spirit of innovation

MD, an industry leader in phase change technology for IC testing covering a wide spectrum of IC products. With missions of Phase change technology and wide range of thermal solution sold worldwide more than 13 years, MD has established its reputation over the years and continues to reinforce it with world class support and creative ways to keep the systems operating reliably and efficiently.

It is also the first company to invent a uniquely designed change phase direct contact TCU. Coupled with an integrated controller and its proprietary direct contact change phase, has raised the standard in direct contact thermal solution.

Brilliant ideas & pioneering solutions

Mechanical Devices support semiconductor companies with brilliant ideas & pioneering solutions.

MD create value for the development of IC devices that are changing life.

The company designs and builds innovative thermal control units for testing IC devices over temperature during engineering and production stages. MD offers highly flexible, state of the art cost effective solutions that provide its clients with the ability to test their IC devices reliably and efficiently.

Brilliant ideas & pioneering solutions

Mechanical Devices support semiconductor companies with brilliant ideas & pioneering solutions.

MD create value for the development of IC devices that are changing life.

The company designs and builds innovative thermal control units for testing IC devices over temperature during engineering and production stages. MD offers highly flexible, state of the art cost effective solutions that provide its clients with the ability to test their IC devices reliably and efficiently.

Quality without compromise

Detailed analysis of reliability tests in development and production, advanced manufacturing techniques and an uncompromising quality management are the basis for the consistent implementation of high quality standards.

Quality without compromise

Detailed analysis of reliability tests in development and production, advanced manufacturing techniques and an uncompromising quality management are the basis for the consistent implementation of high quality standards.

Worldwide 13 months warranty

MD warranted for all TCU’s an extended warranty of 13 months – as an expression of their superior quality in terms of functionality, performance, workmanship, durability and safety.

Worldwide 13 months warranty

MD warranted for all TCU’s an extended warranty of 13 months – as an expression of their superior quality in terms of functionality, performance, workmanship, durability and safety.

Safety

Safety of the user and ease of use are clearly a priority for us. All devices from MD are developed and manufactured exclusively in Israel and labelled with “CE” and “Made in ISRAEL“. It guarantees a high product quality and is internationally protected.

Safety

Safety of the user and ease of use are clearly a priority for us. All devices from MD are developed and manufactured exclusively in Israel and labelled with “CE” and “Made in ISRAEL”. It guarantees a high product quality and is internationally protected.

Whether you have question about Thermal requirement,

thermal solution, demo, evaluation or anything else,

our team is ready to answer all of your questions

Contact us

Let’s Talk / Schedule an

online DEMO Today!

Thermal Forcing Solution

Has Never Been Easier

CONTACT US

Among Our Clients

Among Our Clients